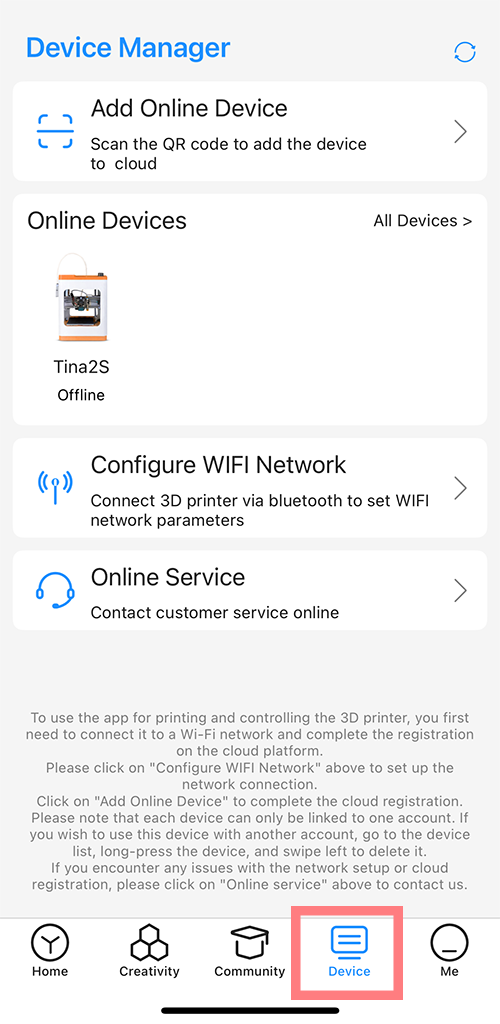

Please check whether this interface is currently linked to a machine.

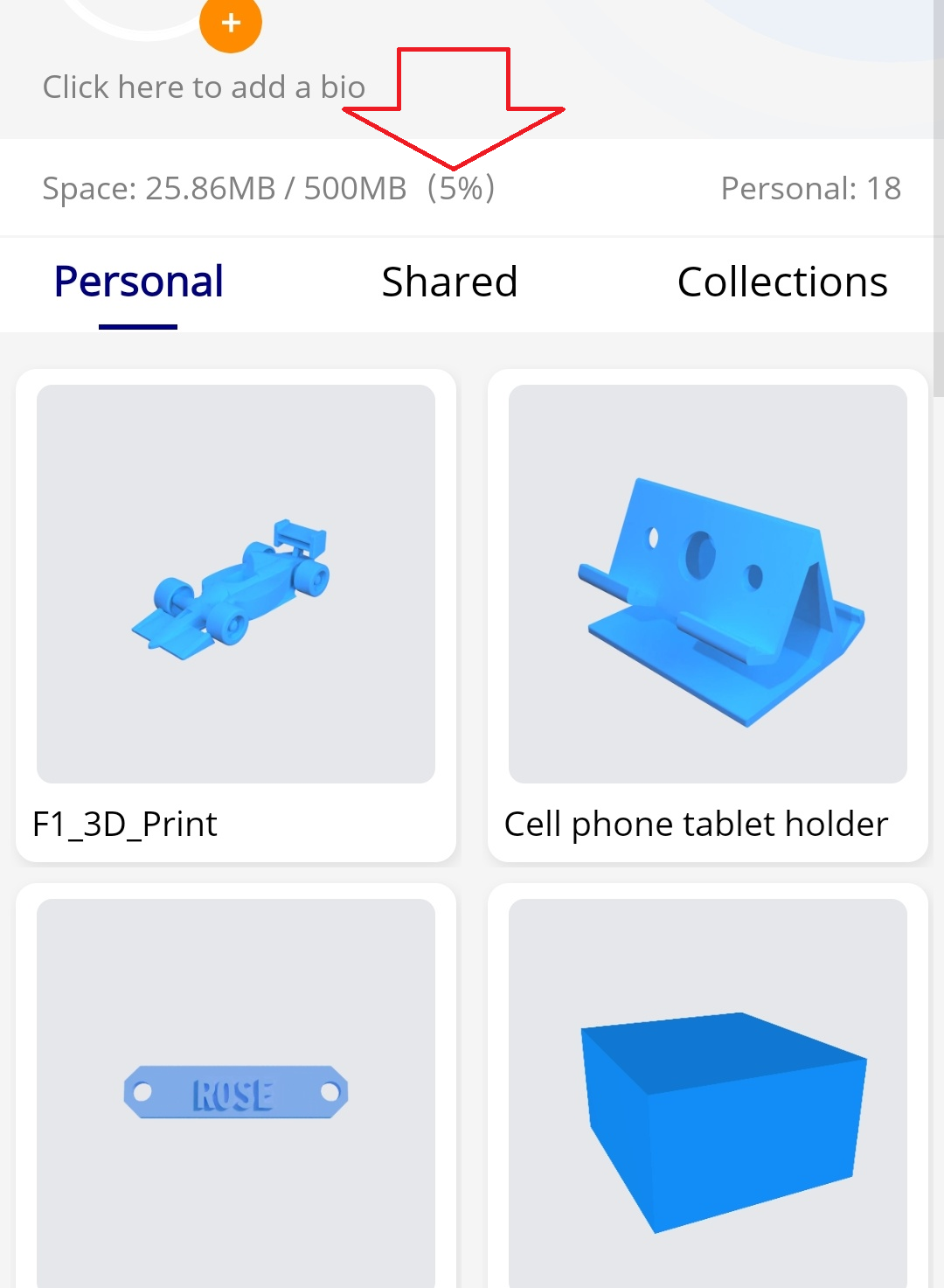

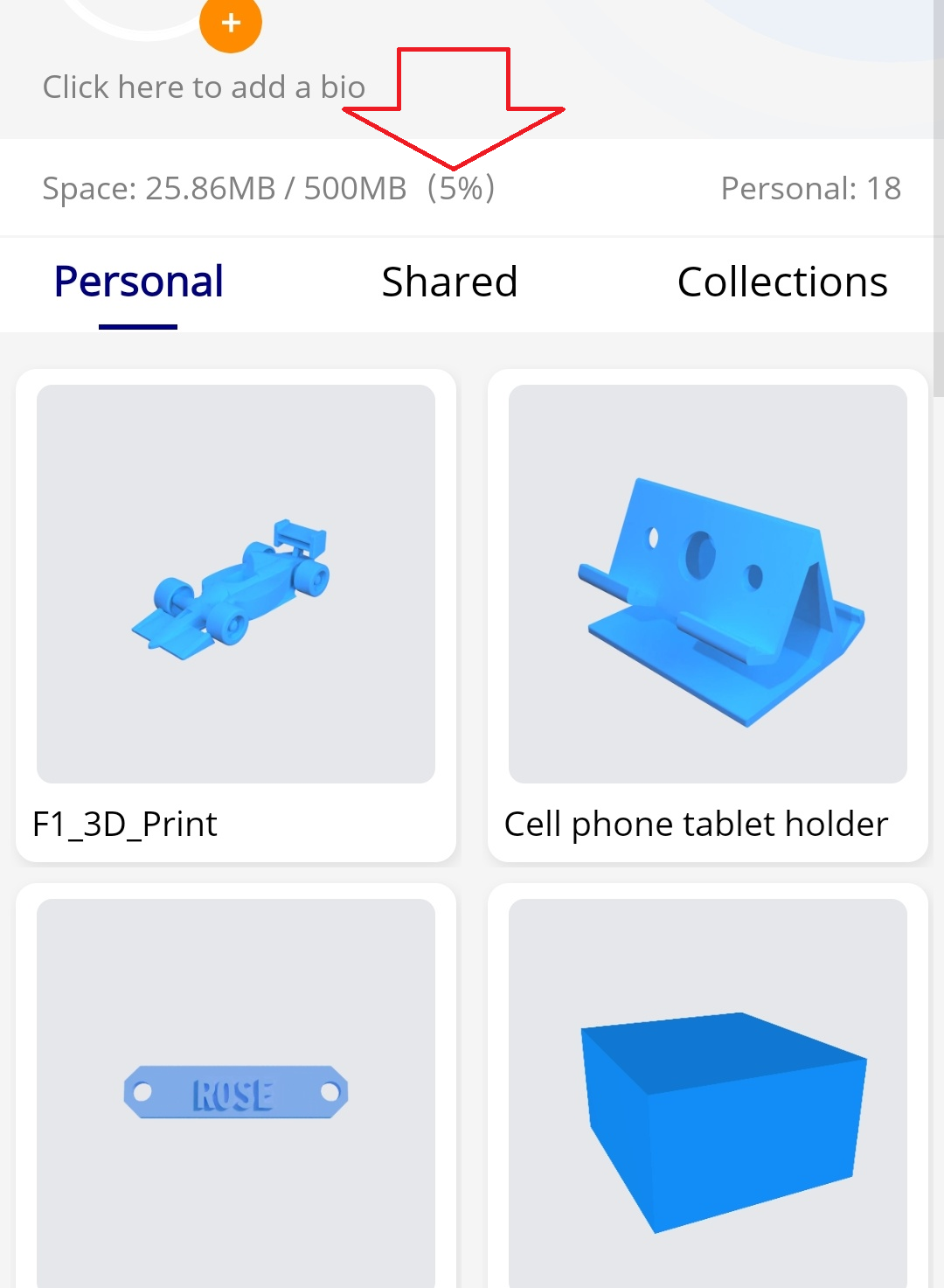

If it is connected, kindly verify whether the model library has sufficient available storage space.

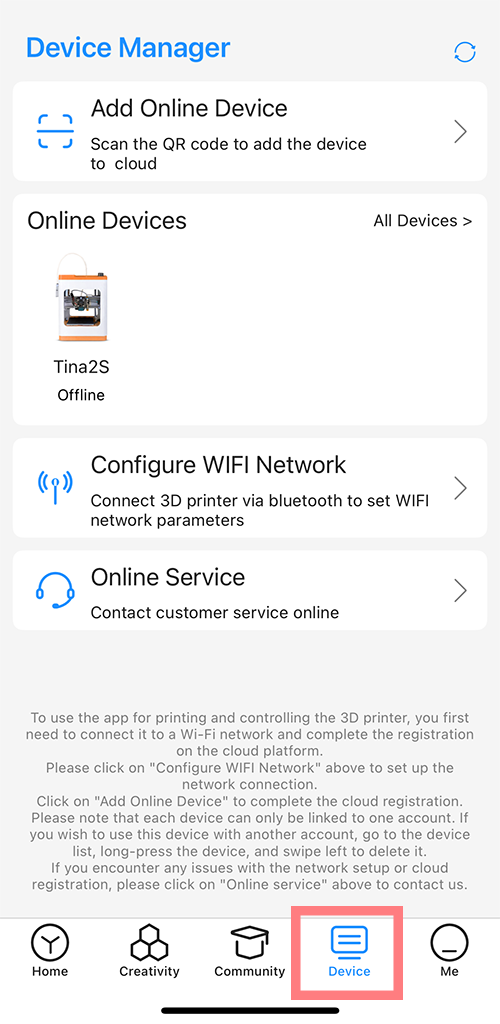

Please check whether this interface is currently linked to a machine.

If it is connected, kindly verify whether the model library has sufficient available storage space.

@Kids-3d-printer Here're some guidance on creating your own 3D models for printing:

2. Downloading Files from Websites:

@Andrei-Stoica The ambient room temperature or the specific filament material can indeed influence the overall printing results. To achieve the most optimal outcome, we highly recommend printing the temperature tower file designed for PLA filament, which is provided at the end of this document.

https://szwzsw.zohodesk.com/portal/en/kb/articles/how-to-determine-the-optimal-printing-temperature-for-your-new-filament

The download link can be found at the bottom of the document. You may copy the files to your TF card to begin printing. If a computer is not available, please don’t worry—the packaging includes an adapter that allows you to transfer the files to the TF card using your phone, so you can continue with printing smoothly and without any difficulty.

@Moore-Fun - You can download your favorite files from websites like:

- Thingiverse

- Cults3D

- Free3D

That’s actually not how it works. The printer uses a separate first-layer temperature setting. If you change the temperature right at the beginning of the print, you are only modifying the first-layer temperature, which means the temperature for the remaining layers may not update accordingly.

If you adjust the temperature directly on the machine, please make sure to wait until the first layer has finished printing before changing the value. Otherwise, the modification may not apply as expected.

Additionally, ambient room temperature and the specific filament material can indeed affect the final printing result. To achieve the most optimal performance, we strongly recommend printing a PLA temperature tower test file to determine the ideal temperature for your filament.

You can find the instructions here:

How to determine the optimal printing temperature

How to determine the optimal printing temperature

The download link is located at the bottom of the document. Please copy the files to your TF card and start printing.

If you don’t have access to a computer, there’s no need to worry. The package includes an adapter, allowing you to transfer files to the TF card using your phone, so you can proceed smoothly without any difficulty.

@nolando13 Here're some guidance on creating your own 3D models for printing:

2. Downloading Files from Websites:

@apple_user_1771074321 I would like to provide you with some helpful information on how to get started with 3D printing using models available online. Here’s a step-by-step guide to assist you:

Download 3D Models: You can find a wide variety of 3D models to print from the following websites:

Extract the Model Files: Once you find a model you like, download the file to your computer. These files are typically compressed in ZIP format. To access the model, you will need to unzip the file, which will reveal the STL file. The STL file is the standard format used for 3D printing.

Prepare the Model for Printing: The next step is to prepare the model for printing, which involves slicing the STL file. This process converts the model into layers that your 3D printer can understand. Depending on your setup, you can do this using the following options:

Feel free to reach out if you have any questions or need further assistance with your 3D printing projects.

The link I previously shared includes a tutorial for the desktop software. You can follow the instructions to slice the file, then copy the generated file to your TF card and proceed with printing.

@Emma-France Here're some guidance on creating your own 3D models for printing:

2. Downloading Files from Websites: